Pipe And Cable Laying Systems

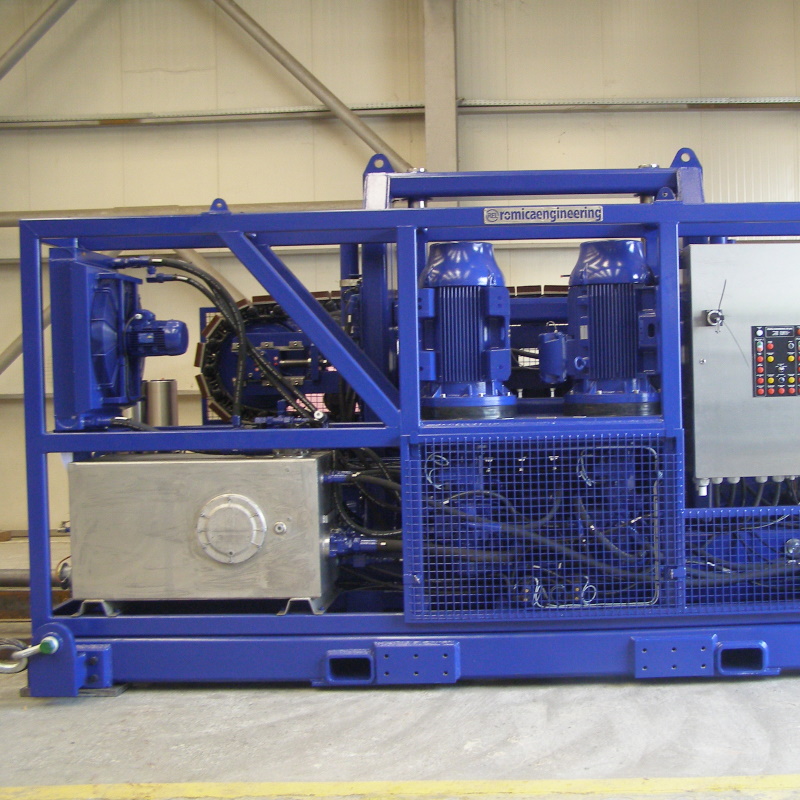

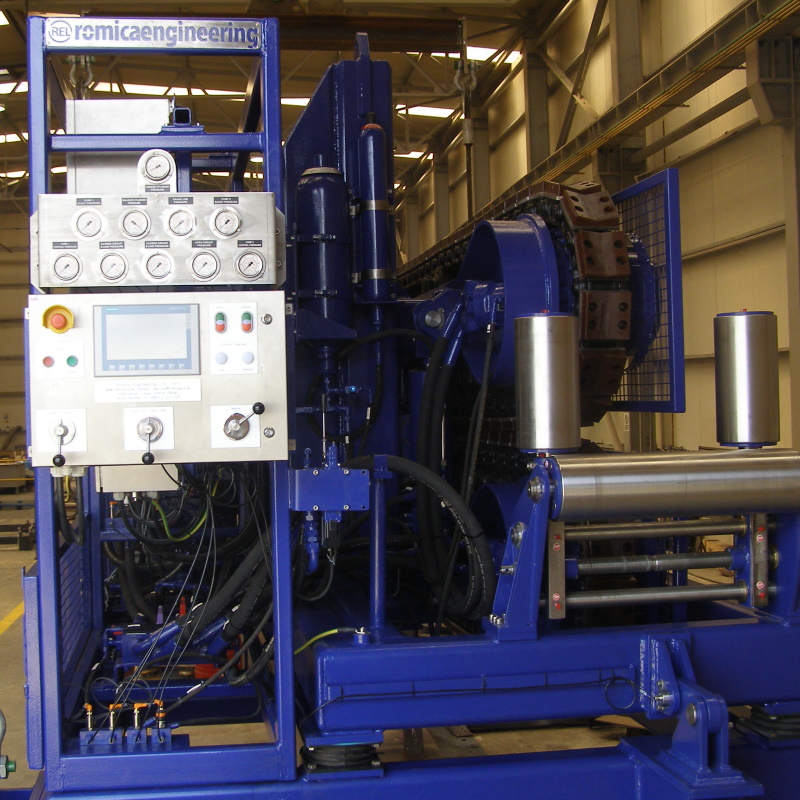

The Romica Engineering self-contained electro-hydraulic 2 track tensioner is designed to operate in an open deck working environment. The tensioner is completely self-contained, on a common skid, and requires only an electrical power supply to the tensioner and optional remote control cabin. A single Ethernet cable, 20 metres, provides the necessary control signals between the tensioner and remote console. The self-contained unit can be easily mobilised and transported by road.

Tensioner controls and instrumentation is provided via stay put rotary controllers, illumined push buttons and a 9” HMI screen with a comprehensive alarms and monitoring system.

Tensioners available in the following range 5, 10, 15 and 20Te

5Te Datasheet

| Maximum Tension (Bi-directional) | Manually varied in the range 0 - 5 Te |

| Linear Speed | Variable in the range 0 - 1200 m/hr, 20 m/min |

| Squeeze Tension | Variable in the range 0.5 - 25 Te |

| Static Parking Brake (1.8 x SWL minimum) | Fail safe, maximum holding tension 9 Te |

| Hydraulic Drives | 2 off fail safe braked hydraulic geared motors |

| Track configuration | Dual track, vertically aligned, 600mm stroke |

| Track contract length and guide opening | Track length 2.5m. Symmetrical guide opening. |

| Track Pad Type | V-grooved rubber bonded pads (bolted) |

| Min product friction at SWL | µ = 0.2 |

| Product diameter (standard pad) | 50mm to 450mm |

| Controls | Local and Optional Remote (within control cabin) |

| Supply Required | 3 ph 380/480 V - 50/60 Hz (dual supply) |

| Tension and Squeeze Measurement | X 4 Load pins interfaced with Siwarex weighing modules |

| Integral HPU - provided to provide track squeeze, track open and close and track brake functions. | 2 x 55Kw, variable flowrate 15 - 170lpm max 230 Bar 600 litres Air blast cooling |

| IP Rating | Tensioner IP65, Control Cabin IP55 |

| Tensioner Weight (without cable) | 11000Kg |

| Tensioner (L x W x H) millimetres | 4100 x 2400 x 2950 |

| Control Cabin Weight (without cable) | 2580Kg |

| Control Cabin (L x W x H) millimetres | 1500 x 1500 x 2000 |

10Te Datasheet

| Maximum Tension (Bi-directional) | Manually varied in the range 0 - 10 Te |

| Linear Speed | Variable in the range 0 - 1200 m/hr, 20 m/min |

| Squeeze Tension | Variable in the range 0.5 - 25 Te |

| Static Parking Brake (1.8 x SWL minimum) | Fail safe, maximum holding tension 18 Te |

| Hydraulic Drives | 2 off fail safe braked hydraulic geared motors |

| Track configuration | Dual track, vertically aligned, 600mm stroke |

| Track contract length and guide opening | Track length 2.5m. Symmetrical guide opening. |

| Track Pad Type | V-grooved rubber bonded pads (bolted) |

| Min product friction at SWL | µ = 0.2 |

| Product diameter (standard pad) | 50mm to 450mm |

| Controls | Local and Optional Remote (within control cabin) |

| Supply Required | 3 ph 380/480 V - 50/60 Hz (dual supply) |

| Tension and Squeeze Measurement | X 4 Load pins interfaced with Siwarex weighing modules |

| Integral HPU - provided to provide track squeeze, track open and close and track brake functions. | 2 x 55Kw, variable flowrate 15 - 170lpm max 230 Bar 600 litres Air blast cooling |

| IP Rating | Tensioner IP65, Control Cabin IP55 |

| Tensioner Weight (without cable) | 17500Kg |

| Tensioner (L x W x H) millimetres | 5900 x 2400 x 2950 |

| Control Cabin Weight (without cable) | 2580Kg |

| Control Cabin (L x W x H) millimetres | 1500 x 1500 x 2000 |